Windchill PDMLink

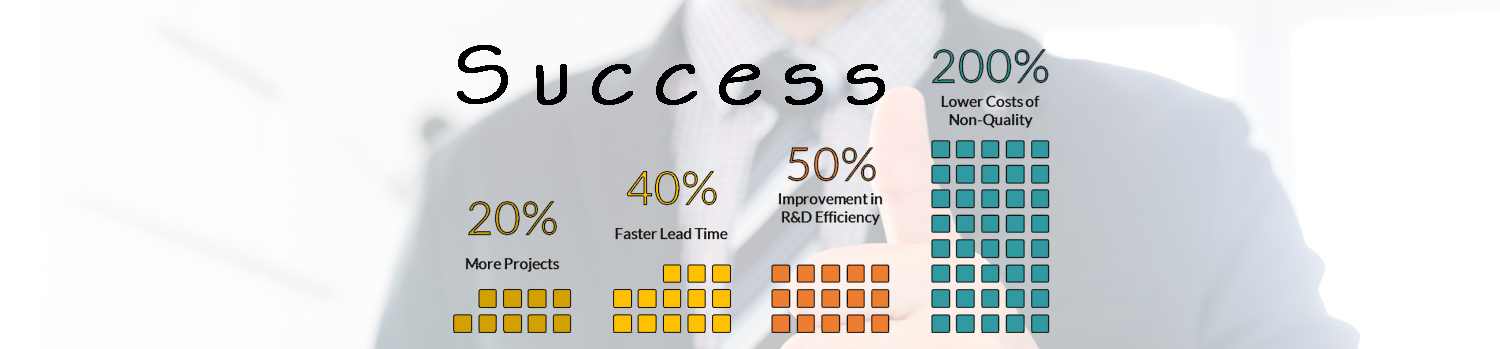

Return of Investment

Windchill PDMLink is a Web-based, industry-proven Product Data Management (PDM) system that supports geographically dispersed teams while managing critical processes such as content, change, and configuration management.

Windchill PDMLink allows you to create and manage product structure views such as “As-Designed” and “As-Planned,” thereby optimizing configuration management.

Order or Request a Quote

Download Product Information

Arsandis Windchill Shots

VISUALIZATION

High Performance Visualization on large complex products with QuickView.

With QuickView users can quickly visualize huge, complex models including filtered configurations in Engineering & Manufacturing structures.

Visualize and collaborate on very large and complex products enabling faster decision-making driving higher quality and faster time to market.

Visualization experiences that are more fluid, faster and seamless.

SMART PLATFORMS

Implement Platform Based Product Design with Windchill Smart Platforms.

Address product family management, downstream interoperability and redundant information to reuse components, reduce engineering effort and extend production capacity.

DIGITAL PRODUCT TRACEABILITY

Capturing and managing customer requirements and regulations across the product development process.

WORKGROUP MANAGER INTEROPERABILITY

Improved flexibility managing upgrades and executing deployments.

CAD DATA MANAGEMENT

Improved customization and Multi CAD integrations driving the Model Based Enterprise across the Digital Thread.

CHANGE MANAGEMENT

Improving change management processes to power the Digital Thread and enable the seamless flow of information.

When it comes to streamlining the product development process, multiple industries use PTC Windchill. Since PTC Windchill is internet-based, companies can operate and coordinate from a number of locations. Company managers and business leaders can easily manage the lifecycle of products and associated service wherever they may be.

Windchill PDMLink was designed to support distributed product development with a Web-based architecture that can coordinate replicated databases around the world. Now anyone, anywhere within the enterprise or extended supply chain can communicate and collaborate on product development. Regardless of location, activities and events can now be monitored, allowing you to identify potential bottlenecks or duplicate tasks.

With a single, complete digital product definition, Windchill PDMLink enhances product quality by eliminating mistakes associated with duplicate or incomplete data. Potential problems can now be identified earlier in the process. With all levels of content–from final assembly structures to individual components–configured, managed and stored in a one central repository, everyone within the enterprise can now immediately access the same product information.

Windchill PDMLink includes a comprehensive Change Management process that can both ‘fast-track’ your simple, lowcost changes and ‘full-track’ extensive modifications, all while automatically documenting revision and iteration histories. Problems caused by miscommunication or delays in conveying product changes are eliminated.

WEATHERFORD

OMRON